Discover the brands and technologies from our business units Henkel Adhesive Technologies and Henkel Consumer Brands.

22 Nov 2021

Why printed electronics are a potential lifesaver

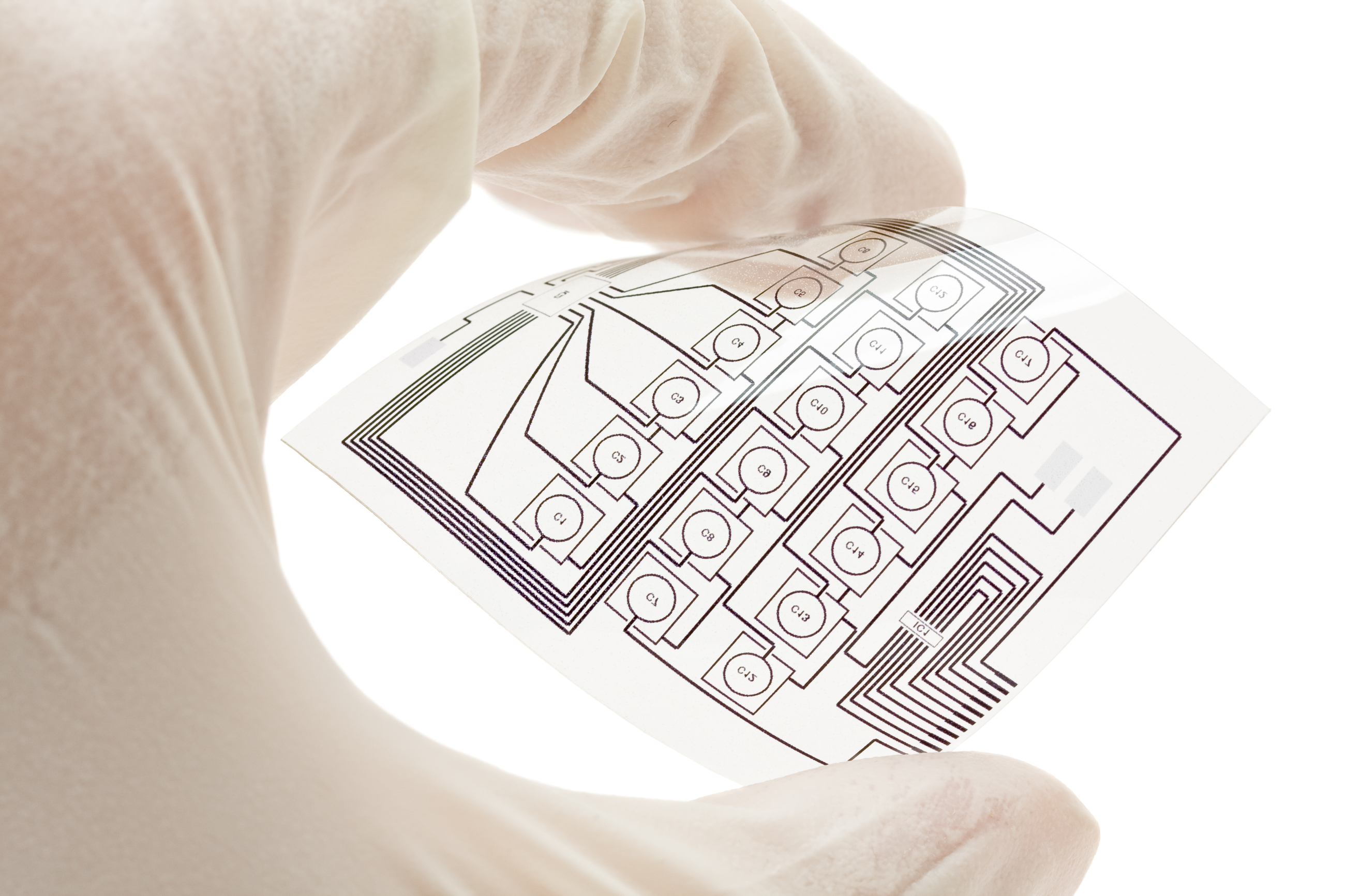

Henkel scientists have achieved major progress related to printed electronics. As such, innovative inks from Henkel are being used to print electronic circuits onto various surfaces or materials, enabling companies, for example, in the healthcare industry to improve the quality of life for patients.

Printed electronics can make almost any object smart. They act as sensors to measure temperature, moisture or touch. Additionally, they are connected to a communication module, which sends data or alerts to the user. In fact, the market for printed electronics is expected to reach $65 billion by 2024, while the global market for electronic skin patches is expected to more than double between 2018 and 2024.

Remote monitoring of patients with COVID-19

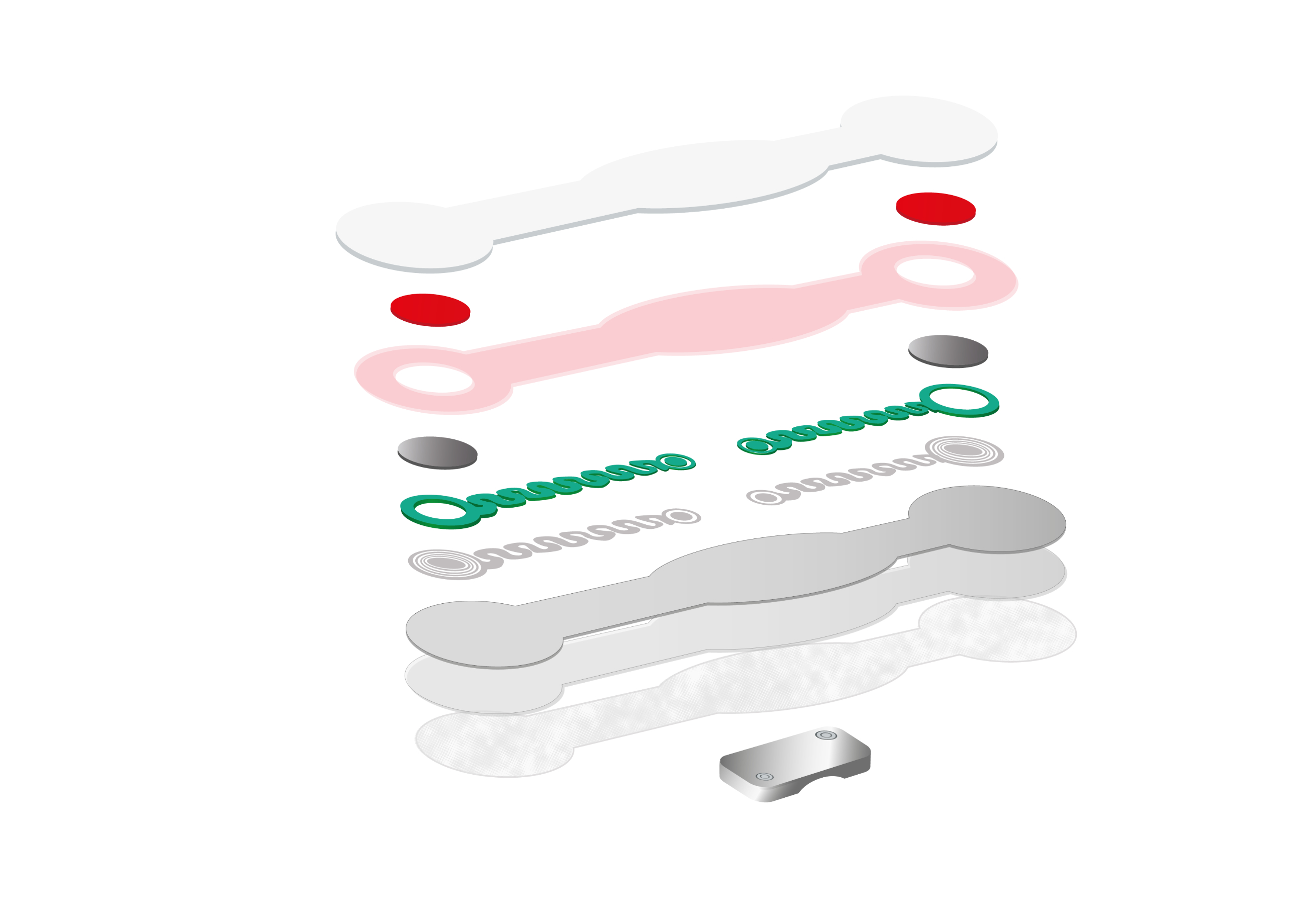

In cooperation with six medical and technology companies, Henkel has developed a smart health patch that allows continuous, remote and wireless monitoring of the respiration, heart rate and temperature of patients. The product – initially set up to monitor the vital functions of patients with heart failure and epilepsy – is now used to monitor COVID-19 patients in more than 20 Belgian hospitals.

Stijn Gillissen, Global Head of Printed Electronics at Henkel, said, “Remote monitoring solutions, such as the smart health patches, have the potential to save time and reduce the exposure of health workers to possible infection.”

The system also offers great advantages to patients in home quarantine or in care homes as it enables them to take and send measurements automatically. They can be certain that the measurements are correct and that they are being monitored constantly. This can offer great reassurance, particularly to elderly people in retirement homes and their families.

Relieving pressure on healthcare systems

As people live longer and the ageing population places strain on the healthcare sector, hospitals or care institutions are starting to use this emerging technology to improve the quality of life for patients. Henkel’s conductive inks, for example, are used to print electronic circuits as moisture sensors onto the inside of diapers for elderly patients. Wi-fi or Bluetooth modules then tell nursing staff when it’s time to change the diaper. The smart diapers increase comfort for the wearer, while also relieving the burden on caregivers and reducing emotional stress that patients sometimes feel when diapers are changed unnecessarily.

Monitoring chronic illnesses

Printed electronics are used in smart patches that help to reduce pressure on healthcare systems related to the rising number of people with chronic illnesses. People with heart conditions, for example, can use these patches to continuously track their ECG, which their doctors can monitor remotely. People with diabetes can use them to monitor blood glucose levels continuously instead of taking blood samples several times throughout the day, which helps them identify exactly the right moment to inject insulin.

Increasing patient comfort

Smart health patches also make it possible to monitor patients’ heart rates, brain activity or breathing patterns remotely. This increases comfort by allowing patients to stay at home, while also reducing the number of visits to clinics or hospitals. Henkel’s conductive inks and special adhesives for attaching patches to the skin are enabling new smart medical devices to be produced in high volume – and with reliable performance.