Discover the brands and technologies from our business units Henkel Adhesive Technologies and Henkel Consumer Brands.

2 Aug 2022 Melbourne

Henkel embarks on local production of Loctite PUR adhesives in Australia

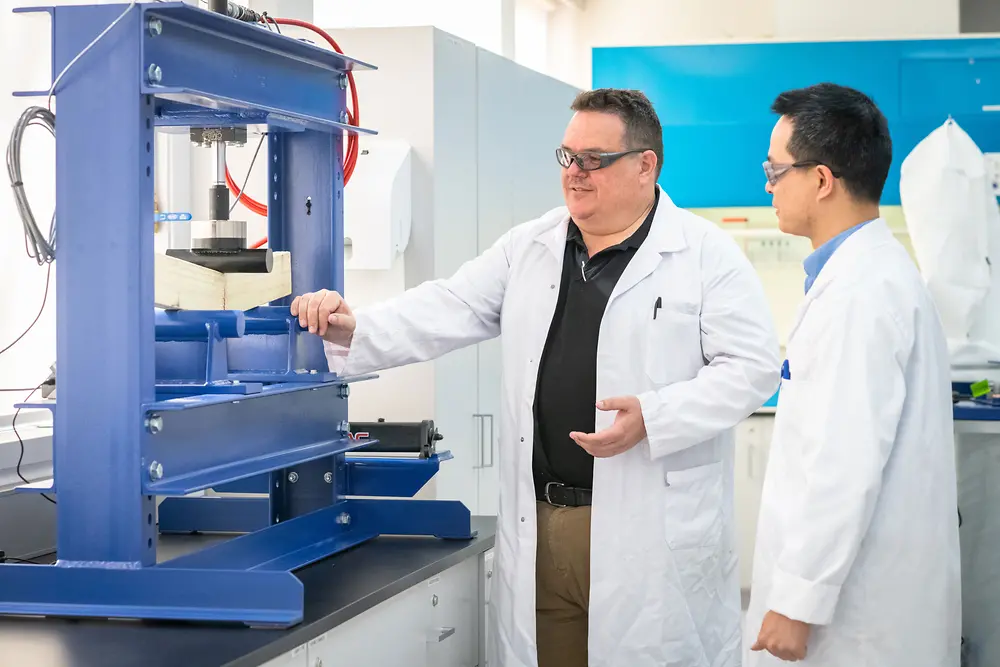

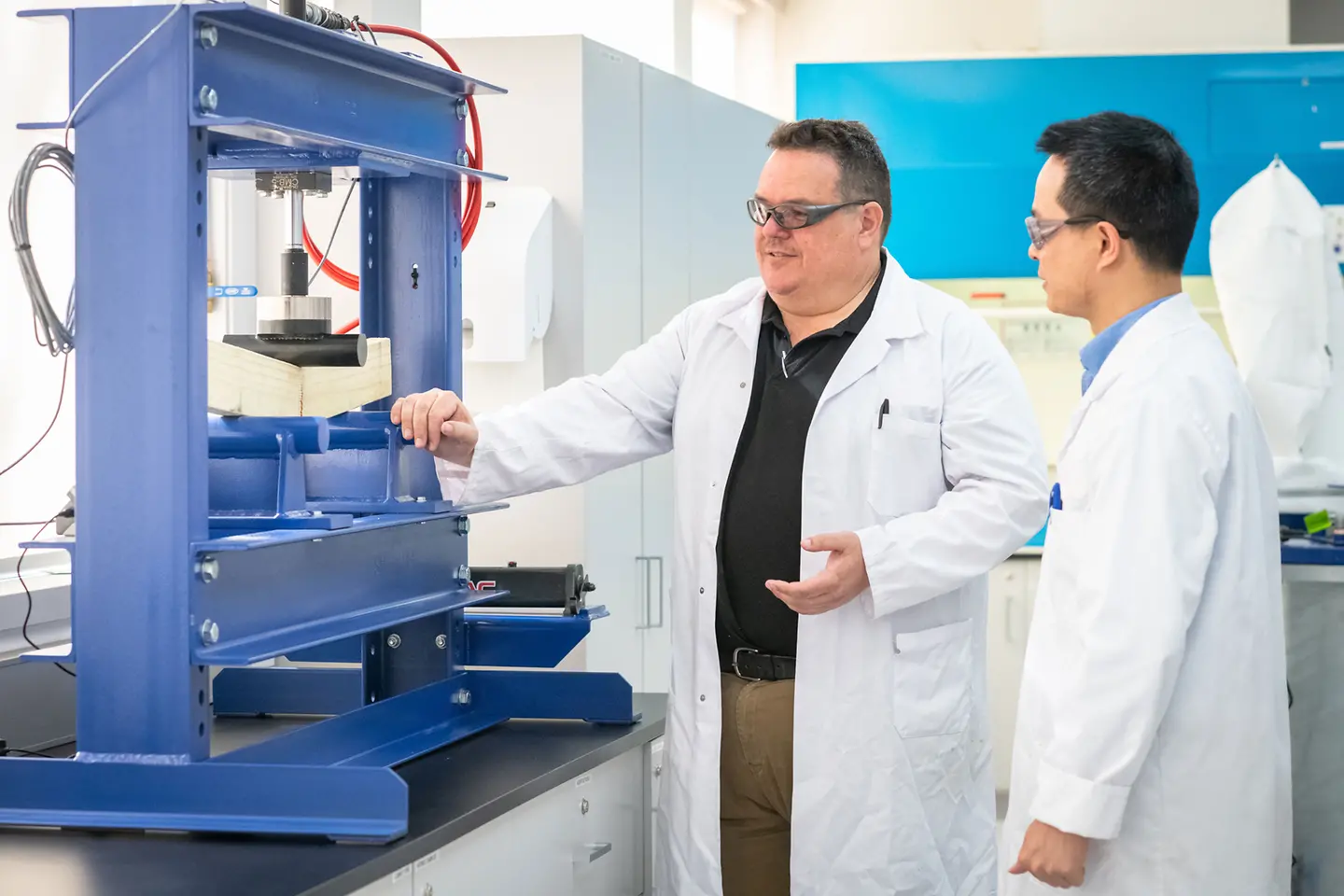

Henkel, a global leader in the adhesives market, is slated to produce Loctite polyurethane (PUR) adhesives in Australia from the first half of 2023. The adhesives will be manufactured in Kilsyth, Victoria, to serve the engineered wood industry across Australia and New Zealand.

“Purbond adhesives are used globally and have long been the benchmark for innovation and reliability in the engineered wood industry. Producing Purbond locally is an exciting endeavor that opens many opportunities for us to help our customers in Australia and New Zealand to grow,” said Brad Simpson, Sales Manager and Business Unit Manager, Adhesives Technologies, Engineered Wood, Furniture and Building Components.

Henkel’s adhesive experts at its Innovation and Application Labs in Sydney and Auckland, help customers explore ways to expedite the time to market and optimize their own production processes for the development of engineered wood solutions. With the production of Purbond in Australia, adhesives production can be customized for specific performance requirements such as fire resistance and for use with modified timbers.

“By localizing the production of Purbond adhesives, our customers will benefit from reduced lead times from order to delivery, as well as greater supply chain security. This reflects our commitment to putting our customers at the center of what we do,” said Warren Grigsby, Business Development Specialist, New Zealand.

Purbond adhesives for engineered wood construction

With a growing environmental awareness surrounding construction and material use, engineered wood has become an increasingly popular design choice for load-bearing mass timber and high-tech structural engineering applications.

Approved for use in all major engineered wood construction markets, Loctite Purbond adhesives make it possible to manufacture glued wood components that are free from harmful industrial solvents and formaldehyde. In addition, they can be specifically engineered and controlled to enable the use of engineered wood in ever-new ways.